A Pipeline’s First and Best Defence

A pipeline’s first and best line of defense against corrosion damage is the external coatings.

Coatings are only one of many methods, technologies, and practices used to ensure pipeline integrity from design and construction to operations, maintenance and retirement.[1]

Related: Effective Supplier Quality Surveillance (SQS).

Fusion Bonded Epoxy (FBE) is a powder coating that provides buried line pipe with an external electrically insulated and moisture-resistant, anti-corrosion barrier against the environment. At typical application temperatures (e.g., 180 – 250 °C [356 – 482 °F]), the FBE powder melts into a liquid before solidifying, because of the heat-assisted chemical cross-linking. This process is known as fusion bonding.[2]

A dual layer abrasion-resistant FBE is applied to provide buried line pipe with additional protection against damage during installation at crossings (e.g., under roads, waterways, and utilities). Liquid epoxy coatings are applied to the field and shop bends, and field welds. Other coating systems may also be used.

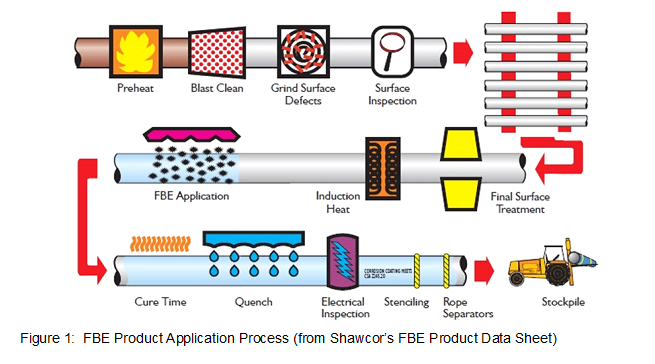

FBE is facility or plant-applied to line pipe for optimal quality assurance and quality control (QA/QC). See the FBE product application process in Figure 1. FBE is required to meet specific industry standards (e.g., CSA Z245.20, CSA Z662, and NACE SP 0394) and owner specifications, and is applied using a project-approved inspection and test plan (ITP).

The ITP details the technical and quality requirements for application including materials receiving, acid washing, abrasive surface preparation (e.g., grit blasting), coating application, visual and holiday (jeep) testing, repairs, laboratory testing, calibrations, marking, storage, and shipment.

FBE offers pipelines long term corrosion resistance, over decades of in-service use, for liquid products to be safely delivered to their customers.

If you have enjoyed a modern lifestyle with 1st world convenience and luxury, thank our pipelines. If you want to enjoy a modern lifestyle with 1st world conveniences and luxuries forever in the future, thank our pipeline coating suppliers, applicators, and inspectors.

For more information about pipeline integrity and safety, see the resources linked below.

- https://prpipelines.com/en/safety/

- https://www.shawpipe.ca/spp/solutions/fbe.html

- http://www.capp.ca/~/media/capp/customer-portal/publications/155642.pdf

- https://www.nace.org/uploadedFiles/Corrosion_Central/Pipeline%20Corrosion.pdf

- https://www.fraserinstitute.org/sites/default/files/safety-in-the-transportation-of-oil-and-gas-pipelines-or-rail-rev2.pdf

- https://www.canada.ca/en/national-energy-board/news/2017/04/important_pipelinesafetystandardnowpubliclyavailable.html

Note

This article was originally published on LinkedIn 22-Jun-18 https://www.linkedin.com/pulse/pipelines-first-best-defence-roy-o-christensen-ret.

About the Author

Roy O. Christensen is a Welding Engineering Technologist who has over 35 years’ experience with O&G, pipeline, and other projects. He has authored countless instructions, manuals, plans, proposals, reports, specifications, and other documents that continue to drive success for many projects. He is the founder of the KT Project that saves organizations significant money and time, by providing key resources to leverage expert knowledge transfer for successful project execution.

Contact

- Roy O. Christensen

- [email protected]

- +1 403.703.2686

Figures

- Shawcor. FBE Product Application Process (from Shawcor’s FBE Product Data Sheet), https://www.shawpipe.ca/spp/solutions/fbe.html

References

- About Pipelines. What is Pipeline Integrity?. https://www.aboutpipelines.com/en/safety/pipeline-integrity/

- Wikipedia. Fusion Bonded Epoxy Coating. https://en.wikipedia.org/wiki/Fusion_bonded_epoxy_coating