MTR Turnover–What is it Good For? Absolutely Nothin’!

If you think that MTR turnover to owner-users is always required, think again!

It is a commonly held belief with oil & gas (O&G), oil sands, and pipeline projects that material test reports (MTRs) are always required for turnover to the owner-user, but that is untrue. In this article I will describe what MTRs are, how these are used during manufacturing, and when these are mandatory for turnover in the manufacturing record book (MRB) or vendor data book (VDB) to the owner-user for retention as a permanent record.

Related: The Key to Project Success.

I will give specific examples from relevant Acts, Codes, Regulations, and Standards to prove that MTR turnover to the owner-user is usually not required and provide examples to clearly demonstrate how this increases costs but does not add value. I will also describe why this is a problem much more than wasted paper or MBs and recommend best practices that are easily implemented. With this information, projects and owner-users can eliminate headaches and reduce costs, while still maintaining all their quality and technical requirements.

Turnover of MTRs to the owner-user is usually not required, rarely provides the added value that is assumed, and often consumes valuable project resources. Most personnel who specify MTR requirements have no way of understanding the implications or total cost. There are problems with obtaining and properly storing or retrieving significant amounts of material data that has limited usefulness. See the hard copies of project turnover in Figure 1 above (the picture is intentionally blurred) and digital copies of project turnover in Figure 4 below.

DESCRIPTION

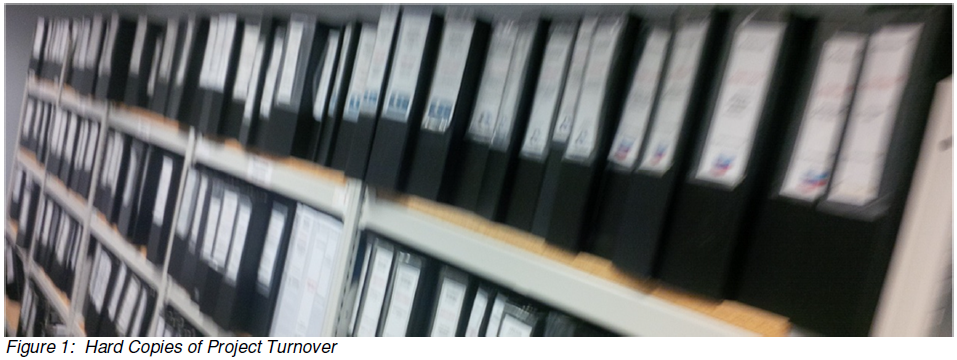

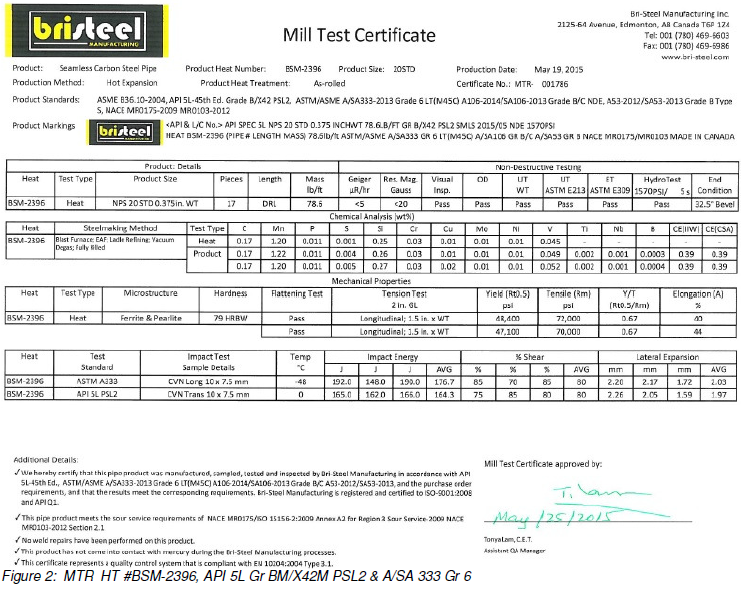

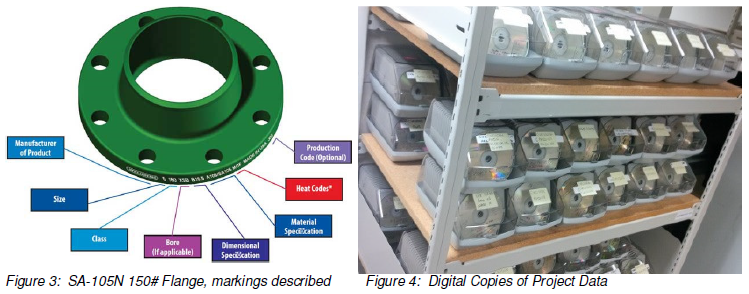

A material or mill test report (MTR) is a quality assurance (QA) document used by material producers in metal and other industries to certify a material’s chemical and physical properties and state compliance with specific standard(s).[1] These standards also require that in addition, the material has specific markings for identification and to certify compliance to the standard(s) (e.g., etched, painted, or stamped). Materials are often produced to meet more than one specification and type (e.g., API 5L Gr BM/X42M PSL2 & A/SA 333 Gr 6). See an MTR in Figure 2 and the flange with markings described in Figure 3.

Materials are produced world-wide, so MTRs may be bilingual including English as well as the language of the country of origin. Reproduction sometimes makes MTRs difficult to read, although clear or original copies can be obtained from the supplier or distributor.

An MTR may consist of one, or a dozen or more pages. There is no standard for how MTRs are formatted, however the necessary information shall be reported. This means that reviewing MTRs is usually not an easy or quick process. The necessary information may not be readily identified and could also need to be compared to the material standard or another reference (e.g., project specification) to verify acceptability and conformance. This is especially true for packaged equipment and piping systems where there are often many similar or different material types used.

MANUFACTURING USE

A supplier’s purchase order (PO) establishes the scope of supply with quality and technical requirements, including documentation to be supplied with shipment and for turnover. Not much more thought may be given to MTR requirements, however, because quality mantras, previous practice, and lack of knowledge all deem this to be a must-have deliverable. The MTRs that are used during manufacturing, filed in the QC records, and then turned over in the MRB/VDB may consist of only a few, or thousands of pages or MBs.

MTRs may be reviewed by suppliers and others at several points during manufacturing to verify that the material meets specified requirements (e.g., purchasing, receiving inspection, material selection and use, and quality control [QC]). The review may be for basic details (e.g., verifying material specification, type, size, and thickness) or the review may also be for specific technical requirements (e.g., verifying carbon equivalence [CE], suitability for low temperature or sour service, or aluminum concentration to avoid nitride embrittlement).

If all necessary material information is not provided by the MTR, then supplementary testing may be needed to verify additional material properties prior to use (e.g., hardness or notch toughness). As another example, when ASTM A703 Supplemental Requirement 23 is invoked for steel castings produced under ASTM A216, A217, and A352, aluminium shall be reported).[2] Additional testing may also be performed for verification purposes (i.e., QC) and positive material identification (PMI).

During manufacturing, quality management programs (QMPs) require material identification to be maintained using either the original markings (e.g., heat numbers [HT #s]) or a system for transferring and coding HT #s such as when material is cut up into pieces. For example, a manufacturer may mark small parts with an identity code 123 because the HT #ABCDEF123456 is too large or would be obliterated during manufacturing. Alternatively, a manufacturer may colour code all incoming materials, to ensure that only the correct material is used where specified.

In these two examples the material is verified, but without traceability, which is rarely a mandatory requirement. Traceability requires the manufacturer to record the specific identity of each material and where it was used by correlating the MTRs to material logs or maps. This may be a straightforward work process for equipment that is made with a few pieces and produced in small numbers. For items that are complex, produced in great numbers, or on a production line, traceability can be time consuming or even impossible (e.g., non-standard work process).

Once manufacturing is completed, these markings may no longer be visible because of processes such as welding, post weld heat treatment (PWHT), and coating. Traceability may be verified after manufacturing for hard stamped markings by examining the original material markings, but for etched or painted markings, traceability records must be produced during manufacturing.

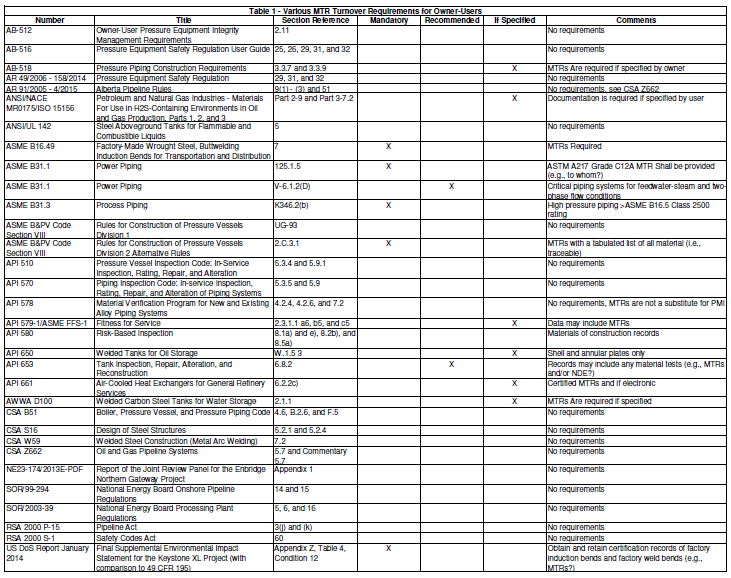

See Bri-Steel Manufacturing’s scan for instant MTR and pipe manufacturing display in Figures 5 and 6 from the 2015 Global Petroleum Show that was held in Calgary, AB.

MANDATORY REQUIREMENTS

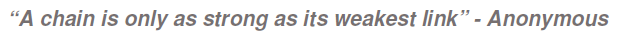

A review of 30 relevant Acts, Codes, Regulations, Standards, and other resources identified only a few specific cases where MTR turnover to the owner-user is mandatory. See Table 1 for various MTR turnover requirements for owner-users.

Of the 30 documents reviewed, only these four have any mandatory MTR turnover requirements:

- API 650, Welded Tanks for Oil Storage, only for shell and annular (bottom reinforcing) plates

- ASME B31.1, Power Piping, only for A217 grade C12A

- ASME B31.3, Process Piping, only for high pressure piping (i.e., >ASME B16.5 Class 2500 rating)

- ASME B&PV Code Section VIII, Construction of Pressure Vessels Division 2 Alternative Rules, all MTRs.

Of these four, only ASME B&PV Code Section VIII, Construction of Pressure Vessels Division 2 Alternative Rules requires a tabulated list to provide traceability.

Of the 30 documents reviewed, only these seven have any MTR turnover requirements recommended or if specified owner-user:

- AB-518, Pressure Piping Construction Requirements, if specified

- ANSI/NACE MR0175/ISO 15156, Petroleum and Natural Gas Industries – Materials For Use in H2S-Containing Environments in Oil and Gas Production, Parts 1, 2, and 3, if specified

- ASME B31.1, Power Piping, critical piping systems for feedwater-steam and two-phase flow conditions

- API 579-1/ASME FFS-1, Fitness for Service, data may include MTRs

- API 661, Air-Cooled Heat Exchangers for General Refinery Services, if specified

- API 653, Tank Inspection, Repair, Alteration, and Reconstruction, material test results and analysis

- AWWA D100, Welded Carbon Steel Tanks for Water Storage, if specified.

None of the other documents reviewed that were reviewed state any requirements for MTR turnover to the owner-user, mandatory otherwise. Requirements are only stated for specifying and verifying materials; nothing more.

ABSA clarified these requirements for pressure equipment in the 1996 article Material Test Reports. Requirements may be driven by being built-in to quality program manuals or customer requirements rather than by Code or ABSA. Obtaining MTRs costs money, storing them costs money, and copying them costs money. On top of that, many off-the shelf items cannot be provided with MTRs, so one would have to wait and pay for testing after the fact, or for a special order to be produced.[3]

For example, CSA S16, Design of Steel Structures and CSA Z662, Oil and Gas Pipeline Systems only state that the standards or specifications shall be recorded and the material be identified prior to use. Therefore MTRs may or may not be used for that purpose.

CSA S16, Design of Steel Structures states that a certificate of conformance (e.g., for the entire project or structure) may be specified. Pipelines have much more detailed and stringent review processes than most any other structures, so the approval conditions of two of today’s highest-profile pipelines were examined; Keystone XL and Northern Gateway.

TransCanada states that the Keystone XL pipeline will be one of the safest pipelines ever built, with 59 special conditions to be voluntarily implemented.[4] Of these special conditions, only #12 relates to MTRs, stating that Keystone must obtain and retain certification records of factory induction bends and factory weld bends.[5] There is no requirement for MTR turnover with any other materials.

After the most comprehensive, scientific review in Canadian pipeline history, the Joint Review Panel of the National Energy Board and the Canadian Environmental Assessment Agency provided its positive recommendation for Enbridge’s Northern Gateway Pipeline, with 209 conditions.[6] None of those conditions require the turnover of MTRs.[7]

OWNER-USER REQUIREMENTS

Projects may use two methods for purchasing materials and equipment. The first is for the suppliers and sub-suppliers to purchase and use project-specific or in-stock items. When the purchase is high-dollar value (e.g., large volume or expensive items) or requires engineering input for quantities (e.g., bulks), items may be purchased by the project and then free-issued to the supplier for manufacturing or construction use. Similarly, owner-users may also purchase an inventory of materials and items that are warehoused for convenient use later. These items are then issued to contractors, manufacturers, or operations as required for small projects (e.g., maintenance and repairs).

When materials and equipment are purchased by the project, the owner-user (i.e., client) Specifications are attached to the PO. These contain detailed engineering and technical requirements rather than documentation requirements, so it is an exception that any MTR turnover requirements are identified therein. Turnover requirements for MTRs are usually specified in the PO as a check box in the document requirements form (i.e., MTRs ☒). There may also be PO or data sheet technical notes to provide additional information or detailed requirements.

Because there are very few mandatory requirements, most MTR turnover requirements originate from the procurement documents. If the person (e.g., requisition engineer) preparing the purchase requisition is inexperienced or unable to specify appropriate MTR turnover, or does not have any guideline to identify what MTR turnover is required, then MTRs are usually required by conservatism or default.

Often there are no explanatory technical notes, so it then becomes the responsibility of others in the supply chain to provide whatever they deem reasonable or typical for MTR turnover. MTR turnover may then be deficient or not meet expectations (i.e., established or assumed).

When the PO has invoked a generic requirement (i.e., MTRs ☒), how will the supplier interpret and apply this requirement for their scope of supply? Without forethought and clearly defined requirements, various questions will inevitably result. For example, what exactly should turnover include? How shall it be formatted? Is traceability required? How will the information be stored and used? How will MTR turnover be provided for purchased vs. free-issued items? And most importantly, what is the cost vs. benefit? Answering each of these questions individually for the close-out of many POs consumes valuable project resources.

AB-512, Integrity Management Requirements states that to ensure the safe operation and reliability of their pressure equipment and compliance with the Safety Codes Act, owners must have effective systems for managing the integrity of their pressure equipment throughout its full lifecycle: from when it is designed, constructed and installed, throughout its service life (operation, maintenance, repairs, alterations, integrity assessments etc.), and decommissioning.

There are cases when MTR turnover to the owner user is appropriate, however these are the exception rather than the rule. These cases should be identified, and steps taken to ensure that MTRs are obtained for critical items and not buried in the thousands of pages or MBs of MTRs for everything else.

For example, chromium-molybdenum steels (e.g., ASME P Number 91) are exotic alloys used in the power generation and nuclear industries. These are creep strength-enhanced ferritic steels (CSEF) that have had creep strength enhanced using a precise microstructure (e.g., with martensite or bainite), that is stabilized during tempering.[8] The exact chemical composition of the base and weld metals must be verified to ensure that the designed creep strength is obtained for safe and reliable in-service use. In this case, the more information the better, and traceability is also advisable.

INCREASING COST BUT NOT ADDING VALUE

A colleague once told me of his experience looking for an MTR for a piece of equipment that was in service at an oil sands facility in Fort McMurray, AB. He knew the HT # and needed to find the MTR. When he went to the document control department to ask for it, he was assured that the MTR would have been turned over by the project. He was pleased he would be able to get it, but then when he asked where it was, he was directed to the warehouse door. It is out there somewhere he was told, help yourself.

When he opened the door he saw rows and rows of shelves filled with hundreds and hundreds of file boxes that contained innumerable pages of MTRs and other data. Somewhere in there was the MTR he was looking for. How exactly then, could all those MTRs that were turned over provide any value for his current need?

It is no different now in the digital age. MTRs may exist, but if you cannot find anything, it is useless information and a waste of valuable resources. This truly is money for nothing. With MRBs/VDBs consisting of thousands of pages or MBs of data, it is more difficult to ensure that other important documents that are required (e.g., manufacturing data reports [MDRs]) are actually obtained.

Another colleague once told me of a project where two types of pipe were delivered to site for the pressure piping and handrails. During construction, these materials were switched and then used incorrectly, with the pressure pipe for handrails and the structural pipe for pressure piping. He did not say if the MTRs were delivered with the pipe or if a review of these could have prevented the problem. He did state that a simple solution to prevent this would be to construct the handrails out of square tubing, so that there could be no confusion. The use of angle sections or fiberglass materials for the handrails would also serve the same purpose.

A large pressure vessel that was made with many parts and would have taken several months to manufacture can be seen in Figure 7. It could have no mandatory MTR turnover requirements. A small but complex piece of equipment for which many MTRs may be requested can be seen in Figure 8. It would have many sub-suppliers with no mandatory MTR turnover requirements.

Anyone who buys a brand-new vehicle is surely thrilled with their purchase. They have taken the time to find and purchase something impressive and valuable that meets their needs and fits their budget. Today’s vehicles are engineered for efficient and safe use, and produced with materials, parts, testing, and inspections to meet specified standards. The vehicles come with manufacturer and/or aftermarket warrantees that assure safe operation and provide a remedy for anything that fails within a specified period.

What would happen, then, if the buyer asked the seller for additional QA such as MTRs with delivery, for the load-bearing and flammable or pressure containing metal components (e.g., fabricated frame, fuel tank, wheel rims, forgings, and castings)? Just like O&G or other projects, the automotive industry may use MTRs during procurement and manufacturing. In addition, material markings for identification and to certify compliance are also used. It is unlikely that any MTRs could be produced with the vehicle delivery however, but even if they could, there would be two outcomes.

The first is that cost would be increased, and delivery delayed. The second is that it would need to be determined what to do with the MTRs and how to use them later. Should a hard copy be put in the glove box with other knick knacks, or a digital copy provided to file on a computer or smart phone? Why not both? Who would review the MTRs? If there was a problem with the vehicle, would the owner still not return the vehicle to the seller for warranty work? If parts were replaced then new MTRs would need to be obtained, to replace those that were superseded.

The materials and equipment procured by projects may consist of single items purchased as bulk supply (e.g., pipe and valves) or packages that include structural, architectural, mechanical, electrical, instrumentation, and other scopes of supply. During technical and commercial evaluations for procurement, documentation is typically not considered, since it is assumed that the project will obtain the necessary MTR turnover. If there is no guideline to identify what MTRs are required, however, it is a recipe for increased costs. That is a hassle for the suppliers, but it is considered a cost of business that is, of course, passed on to their customers.

There are in fact many items for which projects frequently do not require MTRs, so what is different about those? Many low-cost weak link items such as fasteners (e.g., studs and nuts), gaskets, and also non-metal components (e.g., plastic or rubber) typically do not require MTRs. There are two reasons for this.

First, these items are produced with markings for identification and to certify compliance. Second, these items are disposable so that if one is damaged or becomes unsuitable for use, it is discarded and replaced. The cost of obtaining and retaining MTRs for these items is therefore not justified. The same rule of thumb should apply for MTRs with many other materials and equipment (e.g., low cost or off-the-shelf).

When welding consumables are produced the same QA requirements apply as for base metals. That means there are MTRs produced and all items are marked for identification and to certify compliance. Rarely however, are the consumable MTRs requested for turnover. Why should MTR turnover be required for all base metals and yet nothing for the welds produced by one or more welders over several hours, days, or weeks?

PMI is the analysis of a metallic alloy to establish composition by reading the quantities by percentage of its constituent elements. Typical methods for PMI include X-ray fluorescence (XRF) and optical emission spectrometry (OES).[9] Laser-induced breakdown spectroscopy (LIBS) is another method that is now being widely used.

API 578, Material Verification Program for New and Existing Alloy Piping Systems states that PMI confirms that the material which has been or will be placed into service is consistent with the specified alloy material. It also states that MTRs should not be considered a substitute for PMI, but MTRs are an important part of an overall QA program. MTRs are a verification of the material when it is produced. PMI of the materials and welds, however, can be performed at one or more points in the supply chain and after the material has been placed into service.

Advancements with PMI technology have made hand-held devices readily available and more affordable than ever. As a result, PMI is widely used during material processing, production, and distribution. There are also significant advantages for its use during manufacturing. This is discussed in more detail in the section about recommended best practices.

The MTR provides both chemical and mechanical data when the material is produced. PMI testing provides only chemical data, which is the critical information that may be needed after the fact (e.g., for calculating CE). Additional mechanical data must be obtained from destructive testing (e.g., for determining charpy impact or yield strength), however in-situ metallography and hardness testing may be performed. Both are considered non-destructive and hardness correlates linearly with tensile strength.[10]

MUCH MORE THAN WASTED PAPER OR MBs

MTR Turnover that will never be used provides no value and has consumed valuable project resources that are much-needed elsewhere. This is a bigger problem than wasted paper or MBs. Turnover requires many hands and person-hours for compiling, copying, formatting, submitting, reviewing or squad checking, filing and archiving of the paper and/or data. Rework is sometimes also required. Many of these activities occur at the very final stages of manufacturing or supply and even after shipment when it is unlikely that further MTR review will ever be necessary. Ultimately, MTRs may be filed and never used, or even be discarded because they take up too much space.

Many projects are executed with an engineering and procurement (EP) company consulting for an owner-user. The owner-user may rely on the EP for value-added services while the EP may rely on the owner-user to specify project requirements; but that is not the only Catch-22 with MTRs. The work process can be siloed, so that the engineering department only specifies technical requirements while the procurement department manages procurement requirements. As a result, engineering will not question the cost and procurement will not question the need, to ensure that MTR turnover is value-added.

MTRs may be considered a quality-related document, so review of the MTRs is delegated to the quality department by engineering. This is another Catch-22 with MTRs. The MTR reviewer must refer to the procurement documents in order to verify turnover requirements. When MTR turnover is already received, however, it is too late to re-evaluate what is or is not appropriate. The reviewer must accept the MTRs if the PO specified requirements are met, even if these are not necessary or value-added.

When MTR turnover is specified in the PO, it becomes a contract deliverable that is either added to or hidden in the cost by the supplier. For example, there may be a cost-adder of CAD$50 – CAD$100 per line item for providing MTRs (e.g., 12 line items x CAD$100 + GST = CAD$1,260). That may appear reasonable, but when turnover is provided, each item may have the same HT #(s) and therefore the same MTR(s). This is an unnecessary cost for the project, but it is a money-maker for the supplier.

MRB/VDB format may be problematic when turnover consists of thousands of pages or MBs. It is difficult to quickly find relevant data and important deliverables may be buried. Some turnover documentation is simple and straightforward, but there may be many document types to be included, some critical and others not. This may be alleviated by book-marking, but that can be time-consuming and also has a cost. If MRBs/VDBs are difficult to use or are even discarded, why not eliminate whatever is not required or does not add value in order to focus on what is required or does add value?

For example, a Certificate of Inspection Permit allows a boiler or pressure vessel to be placed into service and a Manufacturer’s Data Report (MDR) shall be available for each boiler and pressure vessel.[11] There are similar requirements for piping systems and other components. If the MDR is not obtained or cannot be found in a massive MRB/VDB chock full of MTRs, operations may be shut down or start-up delayed when the Certificate of Inspection Permit is withdrawn or not issued. At that point, MTRs have caused instead of prevented a problem.

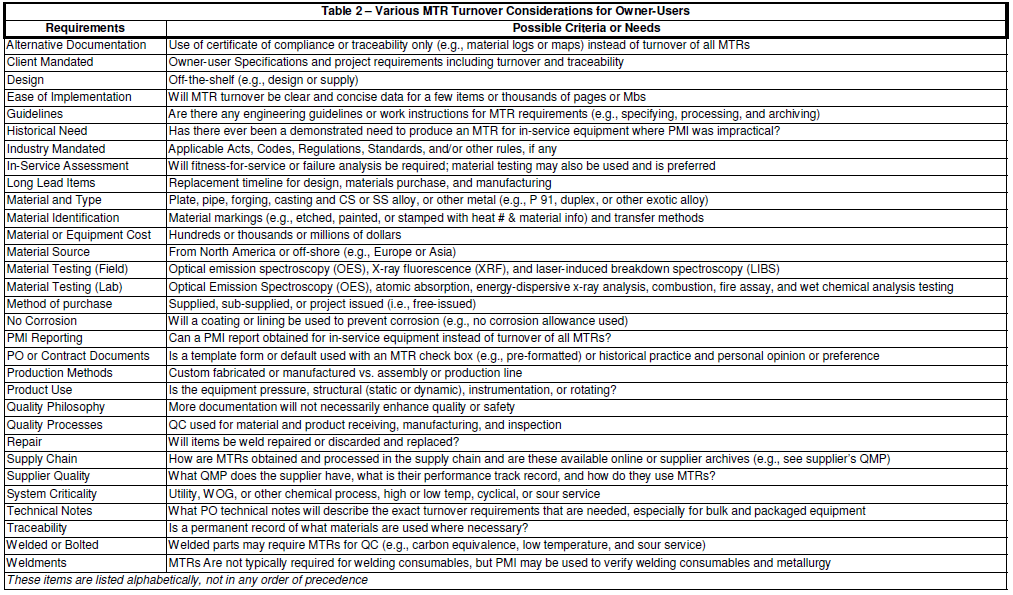

A refinery overview with many platforms, stairs, and handrails can be seen in Figure 9. Would this facility be any safer if the MTRs for these items were included in the MRB/VDB and retained for several decades? A pressure safety device (PSD) with parts shown can be seen in Figure 10. MTRs may be provided for every metal part, of which there are many, but what really is appropriate?

Some producers and distributors are now making MTRs for their products available online, so using the HT #, the MTR can be downloaded by anyone. They are also providing labels with a QR code, so scanning it takes you directly to the corresponding MTR on their website. See Bri-Steel Manufacturing’s scan for instant MTR in Figure 5 from the 2015 Global Petroleum Show. Valuable project resources should not be used to obtain and retain MTRs, when these are only a few mouse clicks away. Some supplier QMPs require MTRs to be obtained and archived for a defined period, so these can be produced later, although not necessarily with a quick turnaround time.

When MTR turnover is not mandatory, manufacturing will follow work processes that are the most efficient and cost effective without it. Items will be produced with quality-controlled materials and systems to meet the specified minimum requirements. If non-standard work processes must then be used to produce MTRs with traceability, the manufacturer will incur additional costs that will be passed on. This is because materials may need to be quarantined either prior to or after manufacturing, while MTRs are obtained, instead of following the production cycle thorough delivery.

Materials and items may be procured with MTRs from one supplier by a project and then free-issued to another supplier, for use in manufacturing their equipment. The MTRs may be turned over to the project by the first supplier and then also turned over again by the second supplier. This may be seen as an efficient work process because the project does not need to file or reference MTRs internally, but turnover of turnover simply increases costs without adding any value. More efficient work processes can and should be used.

Projects often have discrepant requirements with similar items. For example, POs for valves and pressure safety devices (PSDs) that are ordered as bulk and free-issued to suppliers or shipped directly to site often have MTR turnover requirements. This is because the MTR check box indicates yes. The cost is added or included, since suppliers do not provide documentation for free.

When these same items are purchased with packaged equipment, however, there is often no MTR turnover. This is because the supplier purchases these items off-the-shelf and does not specify that MTR turnover is required in their PO. The most appropriate or cost-effective requirements should be identified and used project-wide.

At the beginning of a project everyone may be too busy to think about MTRs, but after the POs are awarded it is too late to make any changes for efficiency improvements. Suppliers accept POs with onerous MTR turnover requirements, but with their eyes wide open. They know their customer will pay for this, or alternately at the end of the project, will waive or not enforce the requirements.

Any changes to MTR requirements after PO award will place the project at a disadvantage. The supplier may use additional or non-standard MTR turnover requirements to request a cost adder. If any requirements are waived however, the supplier may not offer the full value as a cost reduction.

A project may hold back a percentage of PO value as leverage, but this may also be difficult to enforce and ultimately a monetary penalty may be meaningless. Not being paid for MTRs that were not turned over is no incentive to do anything different. The supplier may simply view this penalty as a cost of doing business. Once they have shipped completed items, their focus turns to manufacturing for their next POs.

For pipeline tie-in welds, material information is needed to verify properties (e.g., CE for weldability) after many years or even decades of in-service use. An in-situ PMI test will provide the chemical properties in seconds. If the MTR could be located in a banker’s box or digital file, and if there was traceability, would this data be more reliable than the in-situ PMI? Since the pipeline is buried, a surveyor must confirm the precise location of the pipe and as-built records must also be used to confirm that the original pipe is still in use and was not replaced. If both an MTR and PMI test results are available, what then if there is a discrepancy with the results? Which data is more reliable; the old MTR or the PMI test that can be recalibrated and repeated immediately?

Like all systems with human interaction and data input, errors and omissions will be discovered if MTR turnover is audited. Although it is rare, MTRs may be forged or fraudulently used. MTRs are not fool-proof then, so the document may not truly represent the material or its properties.

Requesting multiple hard copy MRBs/VDBs with additional digital copies increases the cost but adds no value. If there are any changes or corrections made to the MRB/VDB, the previous version and the MTRs may be superseded.

A project may have dozens or hundreds of MRBs/VDBs that are received over a long timeline. A project cannot easily focus on these deliverables and costs upfront when the impact will not occur until many months or years later and especially if the costs and any problems will be borne by others.

Today’s quality mantra is if it isn’t written down, it didn’t happen. So does this mean that everybody everywhere needs an MTR to be produced upon demand, in order to prove that something happened? No, Once a product produced through a QMP has met all quality and technical requirements, it is fit for service.

RECOMMENDED BEST PRACTICES

There are many best practices that projects and owner-users can use to eliminate headaches and save money, while still maintaining all their quality and technical requirements. Specific needs for MTR turnover need to be discussed with internal and external stakeholders upfront, to ensure successful implementation. See Table 2 for various MTR turnover considerations for owner-users.

During project kick-off and prior to any procurement, an instruction should be prepared to specify MTR requirements. A subject matter expert (SME) should prepare the instruction for not only what MTRs are required, but how these will be reviewed and archived for later use. When there are no mandatory or specific MTR needs, turnover should not be added by the requisition engineer just because, or with the hope that it will somehow validate quality. Increasing MTR turnover and traceability requirements does not necessarily increase quality or add value. Wherever MTRs and traceability are not absolutely needed, these should be eliminated.

PO or data sheet technical notes shall be used to specify any detailed turnover requirements rather than only using the MTR check box in the document requirements form. These requirements should be clarified with suppliers before PO award (e.g., bid clarification).

A supplier that receives purchased or free-issued materials for manufacturing may or may not need the MTRs; these requirements should be confirmed prior to PO award. Turnover of turnover must be prevented to avoid unnecessary costs. The project work processes and deliverables need to clearly define what is delivered to whom, when, and in what format. Access to hard and digital data through the supply chain and online should be used to reduce costs.

MRB/VDB turnover should be submitted with a detailed index or table of contents that is reviewed in advance. That is the final opportunity to correct or validate MTR and all other contents before all data is submitted, which may be a significant amount. MRB/VDB turnover should be specified as a single digital record to ensure efficient processing. If MTRs will be voluminous however, these should be prepared as a separate volume instead of being mashed together with all other turnover.

As an alternative to obtaining all the individual MTRs, only a material traceability log or map could be turned over as a record that the materials were correctly used (e.g., types, HT #s, and locations). This manually-produced traceability consisting of one or a few pages could then be used for turnover, instead of thousands of pages or MBs of MTRs.

Better yet, PMI testing may be used to enhance quality and reduce turnover requirements. This practice is not yet widely adopted by manufacturers or projects, but could be with agreement between the supplier, EP, and owner-user. The PMI equipment manufacturer or distributor should also be consulted to develop a suitable program.

For example, MTRs are obtained and reviewed by the supplier and third-party inspector to ensure that the proper materials are used for manufacturing. Upon completion, a PMI survey could identify all parts as correct with an equipment-specific report. This could be done using in-house resources or a non-destructive examination (NDE) contractor. A report with PMI traceability consisting of a few pages could then be used for turnover, instead of thousands of pages or MBs of MTRs.

PMI reporting can be formatted and prepared to suit a range of requirements (e.g., which chemicals and what client or project information is reported). Some hand-held XRF devices also have an embedded camera so that a photograph can be taken of each item that is tested.

Equipment-specific needs must also be correlated to each supplier’s QMP, manufacturing methods, and relevant Codes, Standards, or Specifications, to ensure that MTR turnover is cost-effective and value-added. Specific requirements will vary according to industry, jurisdiction, owner-user needs, and other factors.

CONCLUSION

MTR Turnover requirements are poorly understood by O&G, oil sands, and pipeline projects. During material production and manufacturing, MTRs have specific uses. After turnover, however, MTRs have limited value and are not as easily produced or reliable as a PMI test report. As a result, there are significant opportunities for cost savings and value improvement to be had. In these days of lower-than-desirable oil prices or, anytime for that matter, all options should be considered. Many dollars are being wasted for unnecessary MTR turnover, while project and owner-user management forever wonders how costs can be reduced and timelines shortened.

There are many best practices that can be easily implemented, but there is no one-size-fits-all solution. Continuous improvement may not be easy-peasy, but since when has difficulty been a justification for keeping the status quo? The law of diminishing returns states that in all processes, adding more of one factor, while holding all others constant, will at some point yield lower incremental per-unit returns.[12] MTRs are no exception to this principle; MTRs are not a panacea that will validate quality for everything all the time.

If anyone has another example of where a Code or Regulation specifically mandates that MTRs be turned over to and retained by the owner-user for the operational life of any material, equipment, or system, please contact me. If your organization would benefit from an instruction that provides details for when MTRs and other QC documentation should and should not be required with turnover, please contact the author.

Note

This article was originally published on LinkedIn 7-Jul-15 https://www.linkedin.com/pulse/mtr-turnover-what-good-absolutely-nothin-roy-christensen-ret and by Inspectioneering 19-Sep-16 https://inspectioneering.com/content/2016-09-19/5654/mtr-turnover–what-is-it-good-for–absolutely-nothin-.

About the Author

Roy O. Christensen is a Welding Engineering Technologist who has over 35 years’ experience with O&G, pipeline, and other projects. He has authored countless instructions, manuals, plans, proposals, reports, specifications, and other documents that continue to drive success for many projects. He is the founder of the KT Project that saves organizations significant money and time, by providing key resources to leverage expert knowledge transfer for successful project execution.

Contact

- Roy O. Christensen

- [email protected]

- +1 403.703.2686

Acknowledgements

Michael A. Ell reviewed and provided input for this article. He is a First Class Power Engineer with API 510/570/571/653/580, CWB/CSA W178.2 Level 3, CRM, FRM, and NB AIS certifications, as well as a NB commission.

Carrie D. Grimes proof-read this article. She is a technical writer with a Piping Drafting Certificate and a B.A. Psych. (Adv.) Degree with a French Minor.

Michael A. Ell and Elaine Benes provided inspiration for the title, from Seinfeld Episode #78, The Marine Biologist; Elaine: War–What Is It Good For. Absolutely nothin’! See more at http://www.seinfeldscripts.com/TheMarineBiologist.htm.

Figures

- Hard Copies of Project Turnover, Roy O. Christensen

- Bri-Steel Manufacturing MTR HT #BSM-2396, scanned at the 2015 Global Petroleum Show

- SA-105N 150# Flange, http://www.wermac.org/images/flange_marking.jpg

- Digital Copies of Project Turnover, Roy O. Christensen

- Bri-Steel Manufacturing’s “Scan for Instant MTR” at the 2015 Global Petroleum Show, Roy O. Christensen

- Bri-Steel Manufacturing’s Pipe Manufacturing Display at the 2015 Global Petroleum Show, Roy O. Christensen

- Large Pressure Vessel, http://www.dacro.com/index.php?page=project-gallery

- Lube Oil Console/Skid, http://www.cobey.com/Images/Cobey%20API%20614%20Lube%20Oil%20Console.jpg

- Refinery Overview, http://max-d.ca/images/Refinery.jpg

- Pressure Safety Device (PSD), http://cdn2.bigcommerce.com/server1300/xh55k/product_images/uploaded_images/safety-valves-10.jpg

References

For all references to Acts, Codes, Regulations, and Standards, see Table 1 – Various MTR Turnover Requirements to Owner-User.

- Wikipedia, “Mill Test Report,” http://en.wikipedia.org/wiki/Mill_Test_Report

- Valve Magazine Tuesday, 15 April 2008, “Supplemental Requirement S23 in ASTM A703”, http://www.valvemagazine.com/index.php/magazine/sections/materials-q-a/4270-supplemental-requirement-s23-in-astm-a703?tmpl=component

- ABSA, The Pressure News Volume 1 Issue 2 1996, “Material Test Reports,” http://www.absa.ca/newsletter/v01-1996/v1-iss2.pdf

- TransCanada Keystone XL Pipeline, “Safety,” http://keystone-xl.com/safety/pipeline-safety/

- US DoS Report January 2014, “Final Supplemental Environmental Impact Statement for the Keystone XL Project (With Comparison to 49 CFR 195),” http://keystonepipeline-xl.state.gov/documents/organization/221252.pdf

- Enbridge Northern Gateway, “NEB Conditions,” http://www.gatewayfacts.ca/NEB-Conditions.aspx

- Enbridge Northern Gateway, “Project Joint Review Panel, Appendix 1 The Panel’s Conditions,” http://gatewaypanel.review-examen.gc.ca/clf-nsi/dcmnt/rcmndtnsrprt/rcmndtnsrprtvlm2ppndx-eng.html#ppndx1

- William F. Newell, Jr., PE, PEng, IWE, Euroweld Ltd., “Welding and PWHT of P91 Steels,” http://c.ymcdn.com/sites/www.vma.org/resource/resmgr/2013_technical_seminar/d_1035am_bill_newell_revised.pdf

- Wikipedia, “Positive Material Identification,” http://en.wikipedia.org/wiki/Positive_material_identification

- Wikipedia, “Indentation Hardness,” https://en.wikipedia.org/wiki/Indentation_hardness

- ABSA, “Boiler and Pressure Vessel Permit Information,” http://www.absa.ca/Inspection/BPVPermitInfo.pdf

- Wikipedia, “Diminishing Returns,” https://en.wikipedia.org/wiki/Law_of_diminishing_returns

Tables

- Various MTR Turnover Requirements for Owner-Users

- Various MTR Turnover Considerations for Owner-Users